online delivery mode only

APICS CSCP 5.0 - Certified Supply Chain Professional

供应链职业人专业资格认证

APICS CSCP is a new professional development/education and certification program, which becomes the global standard in supply chain education and certification since its introduction in 2006. It offers a broad view of the field that extends beyond internal operations to encompass all the steps throughout the entire supply chain – from the supplier through the company, to the end consumer. The APICS CSCP Learning System is a comprehensive professional development and exam preparation program. It consists of three print modules and web-based study tools that reflect the entire APICS CSCP Exam Content Manual (ECM) and provides you with a broad view of global end-to-end supply chain management.

The CSCP Learning System:

Module 1: Supply Chains, Demand Management, and Forecasting

Module 2: Global Supply Chain Networks

Module 3: Sourcing Products and Services

Module 4: Internal Operations and Inventory

Module 5: Forward and Reverse Logistics

Module 6: Supply Chain Relationships

Module 7: Supply Chain Risk

Module 8: Optimization, Sustainability, and Technology

CSCP is warmly welcomed by the high-level supply chain management professionals and the consultants from the world when it first comes to the market. Till end of 2013, the fact is:

★Over 32,000 APICS CSCP Learning Systems sold

★Over 24,000 APICS CSCP exams administered

★Almost 15,000 APICS CSCP designees working worldwide

APICS CLTD - Certified in Logistics, Transportation and Distribution

The APICS Certified in Logistics, Transportation and Distribution (CLTD) designation assess individuals based on a comprehensive body of knowledge, best practices and standards for those in the logistics, transportation and distribution industries.

Earning the CLTD credential makes you a recognised expert in the logistics, transportation and distribution fields. Certification demonstrates in-depth knowledge of a broad range of topics to set you apart from your colleagues — proving your high level of knowledge and skills. The CLTD will make you a more valuable asset to your organisation, keeping you and your organisation more competitive in today’s global economy.

The CLTD Learning System:

Module 1 Logistics Overview and Strategy

Module 2 Logistics Network Design

Module 3 Sustainability and Reverse Logistics

Module 4 Capacity Planning and Demand Management

Module 5 Order Management

Module 6 Inventory Management

Module 7 Warehouse Management

Module 8 Transportation

Module 9 Global Logistics Considerations

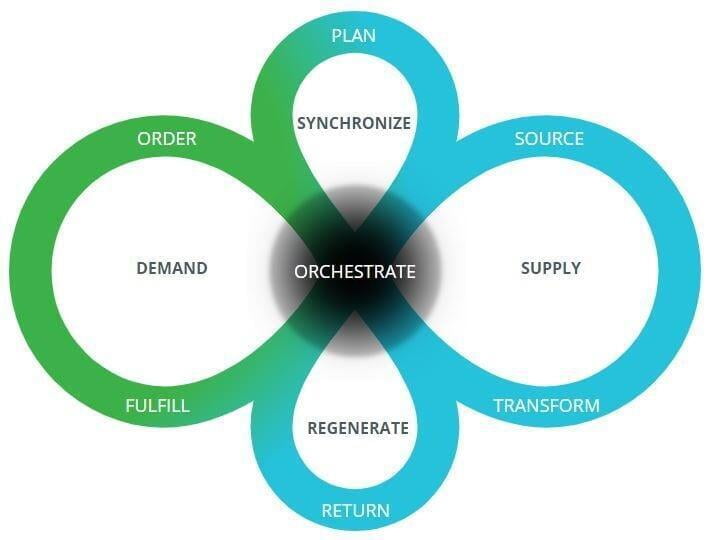

The Supply Chain Operations Reference Digital Standard (SCOR DS) is the only comprehensive, universally accepted and publicly available supply chain standard helping organizations across industries make dramatic and rapid improvements in their supply chain processes.

Implementing SCOR drives results and improves operations.

Typical results include:

- Operating income improvement

- Two-to-six times return on investment in the first year

- Improvement in return on assets for fixed-asset technology investments

- 30% faster digital transformation project implementations

- Reduction in information technology operating expenses through improved use of standard system functions

- Ongoing profit improvement of 0.5%-1% per year

What is NEW in this latest version?

SCOR DS has recently undergone a comprehensive update; modernizing the framework to include sustainability and the digital body of knowledge. This version shifts thinking from a linear supply chain model to a more synchronous network, leading directly to improved business performance.

The CPIM consists of the following content topics:

Module 1: Supply Chains and Strategy Section

1-A: Supply Chains, the Environment, and Strategy Section

1-B: Strategic Scope and Objectives Section

1-C: Developing and Managing Organizational Strategy

Section 1-D: Functional and Operational Strategies

Section 1-E: Production Environments, Types, and Layouts

Section 1-F: Performance Monitoring and KPIs

Section 1-G: Risk Management

Section 1-H: Capital Equipment and Facilities Section 1-I: Sustainability Strategies

Module 2: Sales and Operations Planning

Section 2-A: S&OP Purpose and Process

Section 2-B: Aggregate Demand and Supply Plans

Section 2-C: Reconciling S&OP Plans

Module 3: Demand

Section 3-A: Demand Management

Section 3-B: Sources of Demand/Forecasting

Section 3-C: Forecast Performance

Module 4: Supply

Section 4-A: Creating and Validating the Master Schedule

Section 4-B: Using and Maintaining the Master Schedule

Section 4-C: Material Requirements Planning

Section 4-D: CRP and Scheduling

Section 4-E: Suppliers and Purchasing

Section 4-F: Changes and Product Life Cycle Management

Module 5: Detailed Schedules

Section 5-A: Planning Detailed Schedules

Section 5-B: Scheduling and PAC Methods

Section 5-C: Creating Production and Service Schedules

Section 5-D: Managing Detailed Schedules and Scheduling Materials

Module 6: Inventory

Section 6-A: Inventory Planning

Section 6-B: Inventory and Product Costs, Value, and Metrics

Section 6-C: Itemized Inventory Management

Section 6-D: Inventory Control

Module 7: Distribution

Section 7-A: Planning Distribution

Section 7-B: Replenishment and Order Management

Section 7-C: Waste Hierarchy and Reverse Logistics

Module 8: Quality, Technology, and Continuous Improvement

Section 8-A: Quality

Section 8-B: Technology

Section 8-C: Continuous Improvement